Article

Popular Articles

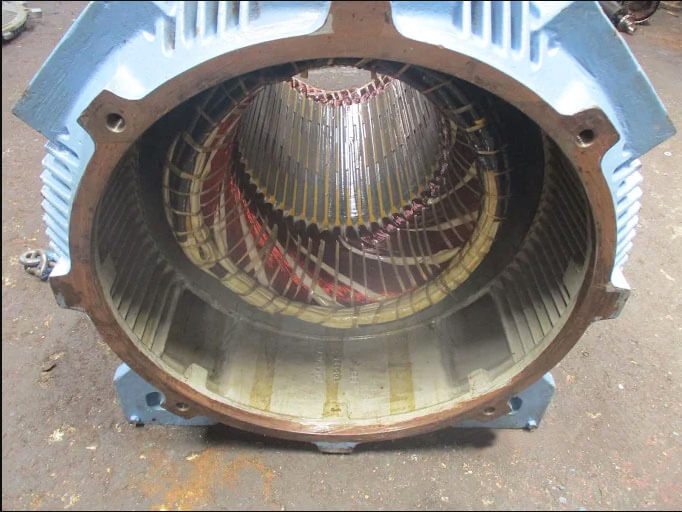

Can a Motor Perform at Its Original Efficiency After Rewinding? A common question in industrial maintenance is:“Can a rewound motor still perform at its original...

Why Electric Motors Sometimes Encounter Random Tripping That’s Hard to Recognize Unexpected or “random” tripping of an electric motor can be one of the most frustrating...

Common Electric Motor Failures — And How We Overcome Them 1. Overheating and Insulation Breakdown Root Cause: Continuous overloading, poor ventilation, or unbalanced...