Why Electric Motors Sometimes Encounter Random Tripping That’s Hard to Recognize

Unexpected or “random” tripping of an electric motor can be one of the most frustrating issues in industrial operation. It often occurs without clear symptoms — the motor restarts and runs fine for hours or days before it happens again. These intermittent faults are difficult to trace but usually point to a combination of electrical, mechanical, and environmental factors.

1. Hidden Power Quality Disturbances

Root Cause: Sudden voltage dips, harmonic distortion, or transient imbalance from upstream equipment or unstable supply.

Effect: Protection relays and overload devices detect abnormal current surges, triggering unnecessary trips even when the motor itself is healthy.

Our Solution:

At TE Teras Tech, we perform Power Quality Analysis using high-resolution analyzers to capture THD-V, THD-I, unbalance, and transients in real-time. We identify the actual source — whether from the supply network, capacitor bank resonance, or nonlinear loads — and propose corrective actions such as harmonic filters or line reactors to stabilize your power system.

2. Thermal Overload or Ambient Influence

Root Cause: Fluctuating load demand, high ambient temperature, or poor ventilation inside motor enclosures.

Effect: Thermal overload relays respond to rising winding temperature and trip intermittently, especially during peak production hours.

Our Solution:

We conduct temperature profiling and thermal imaging to check winding and casing temperature rise. Our rewinding process uses Class H insulation and optimized slot-fill ratio to lower hotspot temperature. Combined with improved cooling path design, this prevents nuisance tripping caused by thermal overloads.

3. Insulation Leakage and Moisture Contamination

Root Cause: High humidity or condensation within terminal boxes and stator windings.

Effect: Gradual leakage current or momentary ground faults cause residual current devices (RCDs) or earth-fault relays to activate randomly.

Our Solution:

We use Motor Circuit Analysis (MCA) to evaluate insulation resistance, polarization index, and phase balance. Motors showing partial leakage are dried, re-varnished, and vacuum-impregnated for complete moisture removal — ensuring reliable insulation integrity under all operating conditions.

4. Bearing Current and VFD-Related Faults

Root Cause: PWM (Pulse-Width Modulated) switching from VFDs can induce shaft voltage, causing bearing fluting or transient discharges.

Effect: Ground-fault relays may sense these spikes as short circuits, resulting in irregular tripping events.

Our Solution:

Our technicians inspect for electrical discharge damage (EDD) and perform ultrasound friction analysis to detect early bearing degradation. We recommend insulated or hybrid bearings, shaft grounding rings, and proper cable shielding to eliminate VFD-related electrical stress.

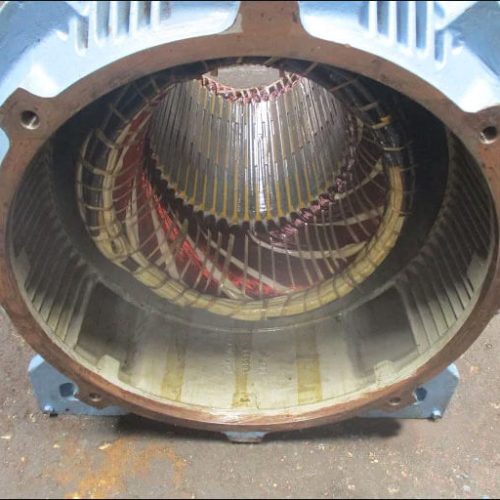

5. Mechanical Imbalance and Rotor Eccentricity

Root Cause: Misalignment, bent shafts, or uneven air-gap due to improper installation or bearing wear.

Effect: Sudden vibration spikes alter current waveform symmetry, fooling protection systems into tripping under the impression of an electrical fault.

Our Solution:

We apply laser alignment and dynamic balancing down to micrometer precision. Our vibration diagnostics verify true mechanical stability, ensuring smooth torque transmission and protecting both bearings and winding from secondary stress.

Moving Toward Reliability and Zero-Failure Performance

Random tripping is rarely “random.” It’s usually a combination of small electrical and mechanical irregularities overlooked during conventional maintenance.

At TE Teras Tech, we combine electrical diagnostics, mechanical precision, and predictive analysis to pinpoint the true cause — turning hidden symptoms into clear, data-based solutions.

Why Choose TE Teras Tech

Since 2002, we’ve specialized in motor and alternator performance management, rewinding, and energy-efficiency optimization.

We go beyond repair — delivering measurable reliability through Motor Circuit Analysis, Power Quality Testing (IEC 60034-30-1 Compliance), and Predictive & Preventive Maintenance programs tailored to your plant’s needs.

Get in Touch

If your motor trips without warning or shows erratic shutdown behavior, don’t leave it to guesswork.

Let TE Teras Tech analyze and stabilize your system for uninterrupted operation.

Contact us today for professional diagnosis and consultation.